What is Rotational-Moulding and Injection-Moulding?

Different Types of Plastic Moulding

What is Rotational Moulding?

Rotational moulding is a form of manufacturing used to create versatile plastic solutions.

Rotational moulding involves a heated hollow mould being filled with the chosen material, before being slowly rotated to allow the material to disperse evenly around the mould.

This allows a customer to design their product from scratch to suit their exact needs and requirements, rather than the alternative of assembling a similar product from several pieces, as well as reducing the costs of materials and assembly.

Similarly, the chosen plastic polymer material will be identified as the best material with respect to providing the finish quality and strength performance required, as well as any special requirements i.e. flame resistance, static-free usage etc.

The rotational moulding process is divided into 4 steps:

- Loading: a mould is loaded with a pre-measured quantity of powdered plastic.

- Heating: under biaxial rotation the mould is heated until the powder is properly dispersed and forms a uniform layer on the inside of the mould

- Cooling: under continued rotation the mould is cooled until the melt is solid.

- De-moulding: the mould is opened and the final product is removed from the mould.

This process results in a robust and high quality product, while due to the reduced costs of materials and assembly is very cost-effective when compared to alternative methods (i.e. injection and blow moulding).

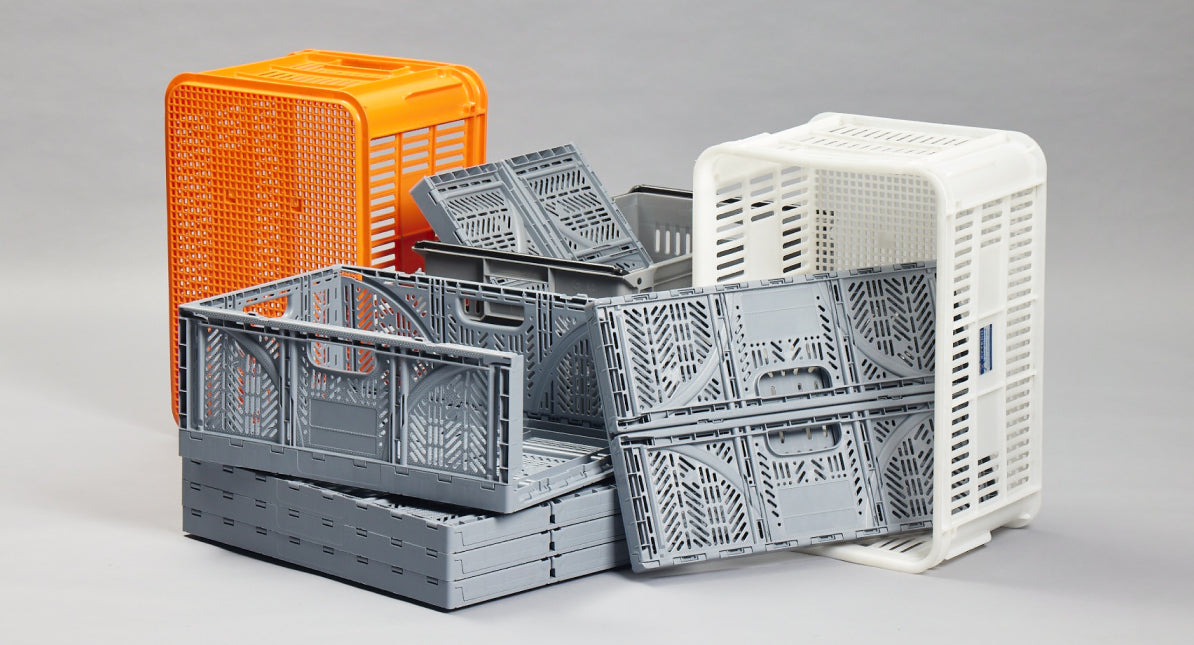

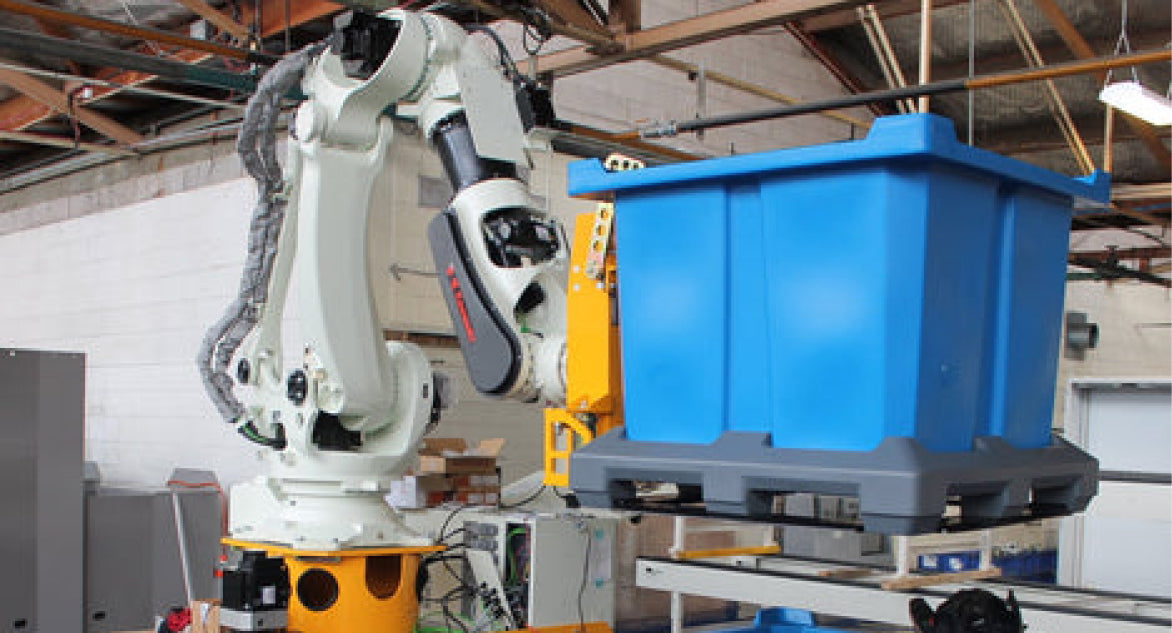

What is Injection Moulding?

Plastic injection moulding is a form of manufacturing used to produce large quantities of the same plastic product in a short span of time. This is the most common method of producing large volumes of finished plastic for commercial and industrial use.

The injection moulding process is divided into 3 steps:

- Molten plastic is injected under high pressure

- This plastic is then pushed into the cavity of a metal die

- Rapidly cooled to form a solid shape

Rotaform is your one-stop solution for producing high precision plastic injection molded parts. We have the capacity to product these parts on a large scale. To find out more about our injection moulding services, contact us on +64 9 275 2144.