Avoid poor quality

PLASTICS ARE WASTE AFTER 5 - 8 YEARS

Unfortunately, supplier decisions often made based on total cost outlay, which means suppliers design minimum cost, leading to worse products, faster breakages and recurring replacement costs.

Thankfully, leading companies have now adopted “cost per year of useful life” as their leading decision factor.

We believe in optimising products for longevity, increasing the lifespan of products and in turn the long term return on investment.

Our Products Are

IMPOSSIBLY DURABLE, LASTING UP TO 25 YEARS

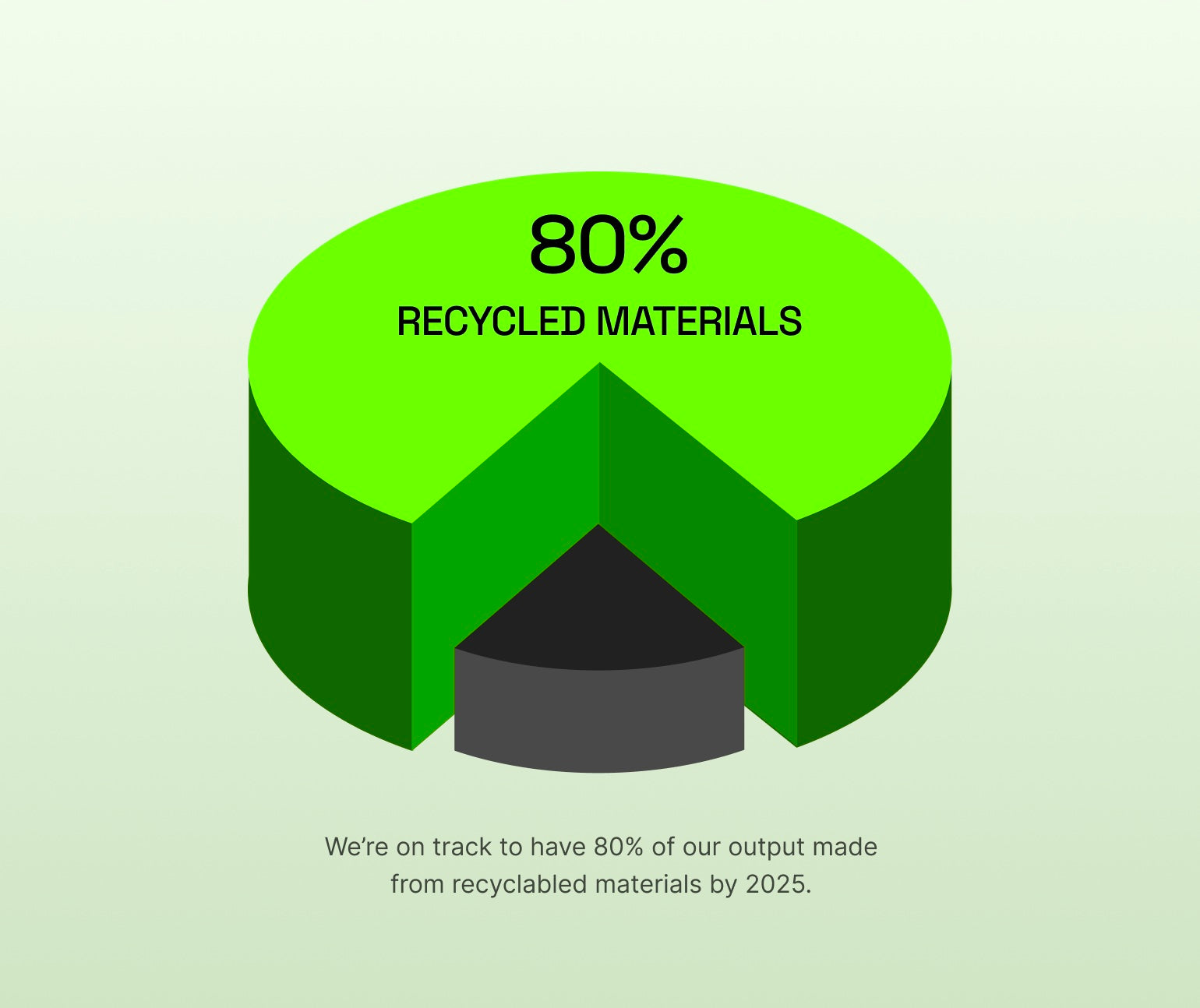

Better product quality is good for business and the environment. With a sustainability focus, we focus our clients consider cost per year-of-useful-life when selecting products.

Our Sustainable Pillars

We are dedicated to our sustainability pillars to create a better future for waste management and returnable packaging.

Product Design

Materials Choices

Manufacturing Practices

Future Thinking

Rotaform Product

Should NOT end up in waste streams

Rotaform removes the need for one way packaging in most supply chains.

- Consistent R&D to improve product sustainability.

- We run sustainability stewardship programs with large customers.

- Ongoing collaboration with industry to create practical solutions for problems.

- All products can be returned and recycled at the end of their life.

HOW CAN WE MAKE MORE

SUSTAINABLE CHOICES

We sat down with the CEO of Rotaform, David Brumby to understand his thoughts around plastic, innovation and sustainability.

- Sustainable practices

- How to choose a supplier

- Price vs Quality

- Our Recycling process

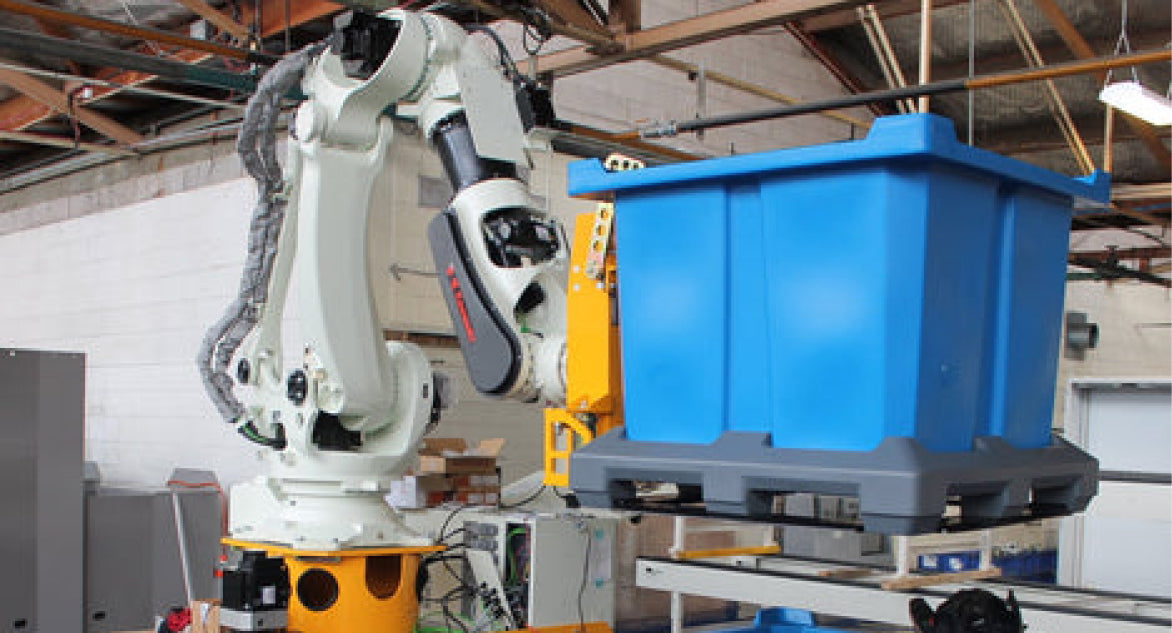

Our circular product lifecycle

No Rotaform product should end up in the landfill. That’s why we create a close loop for all our products.

1. Quality design

Design strong and long-lasting products that use quality materials, and have recycling and repair in mind.

2. Long Useful Life

With durability and UV protected materials, our products continue to be used for 10-25 years.

4. Recycled & Reused

We recycle as much material as possible and create new products that are re-sold.

3. Repairs & replacement parts

With plastic welding and spare parts, products continue for 5 - 15 more years.

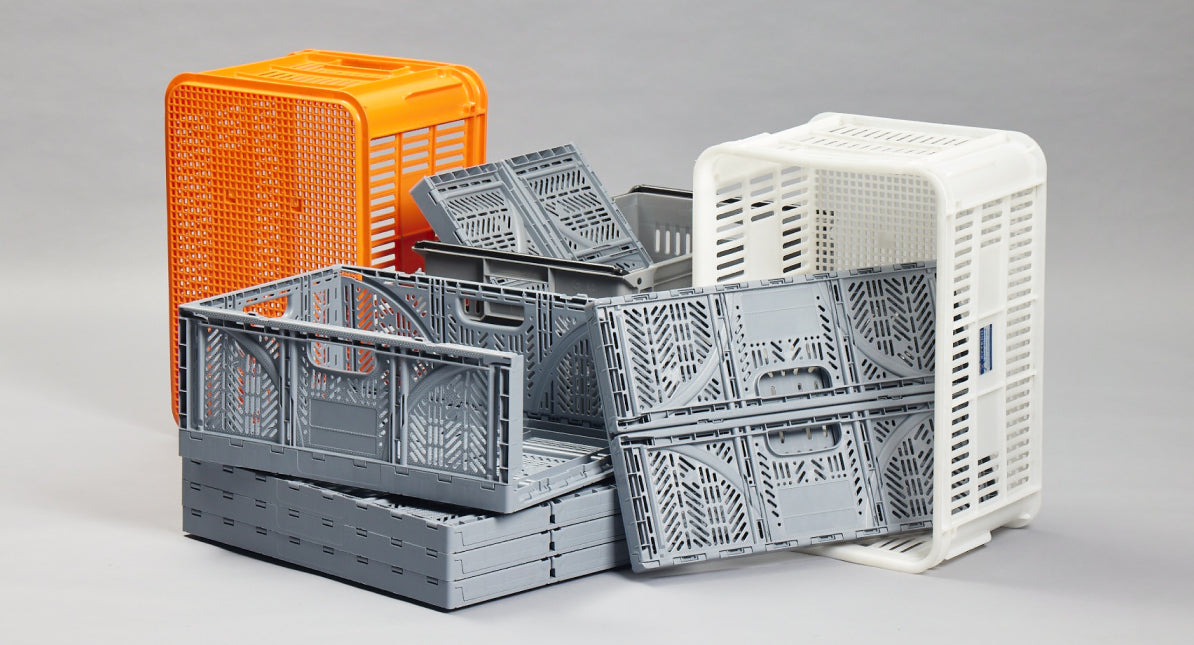

CASE STUDY

WAREHOUSE GROUP

We engineered reusable folding crates that last up to 20% longer and fold down 15% smaller than alternatives, reducing carbon footprint, repairability and useful life.

Trusted by industry leaders for over 40 years