Custom Product Design

With 40 years experience with NZ and Australian companies, our team can design and mould or source almost any plastic product. Our world class designers thrive on designing cost-effective products and using innovative solutions to solve unique industry problems.

We can design and manufacture any plastic product from 1 item to 10 million+ units in 2-8 months (typically). Our experienced team will guide you through making a robust and award winning product that is delivered on time and to spec.

TimeLine

We work with a variety of customers anywhere

Between small family-run businesses to large scale multinational companies.

Between small family-run businesses to large scale multinational companies. For most projects it takes 2 - 8 months from first phone call to your first product delivered. Your delivery timeline depends on the complexity of each project stage (briefing, design, sourcing, testing, approval, manufacturing and delivery).

In some special cases (like for the Rugby World Cup) we have designed and manufactured custom items in as little as 6 weeks.

Choose every detail

We will guide the design process so you can customise every detail.

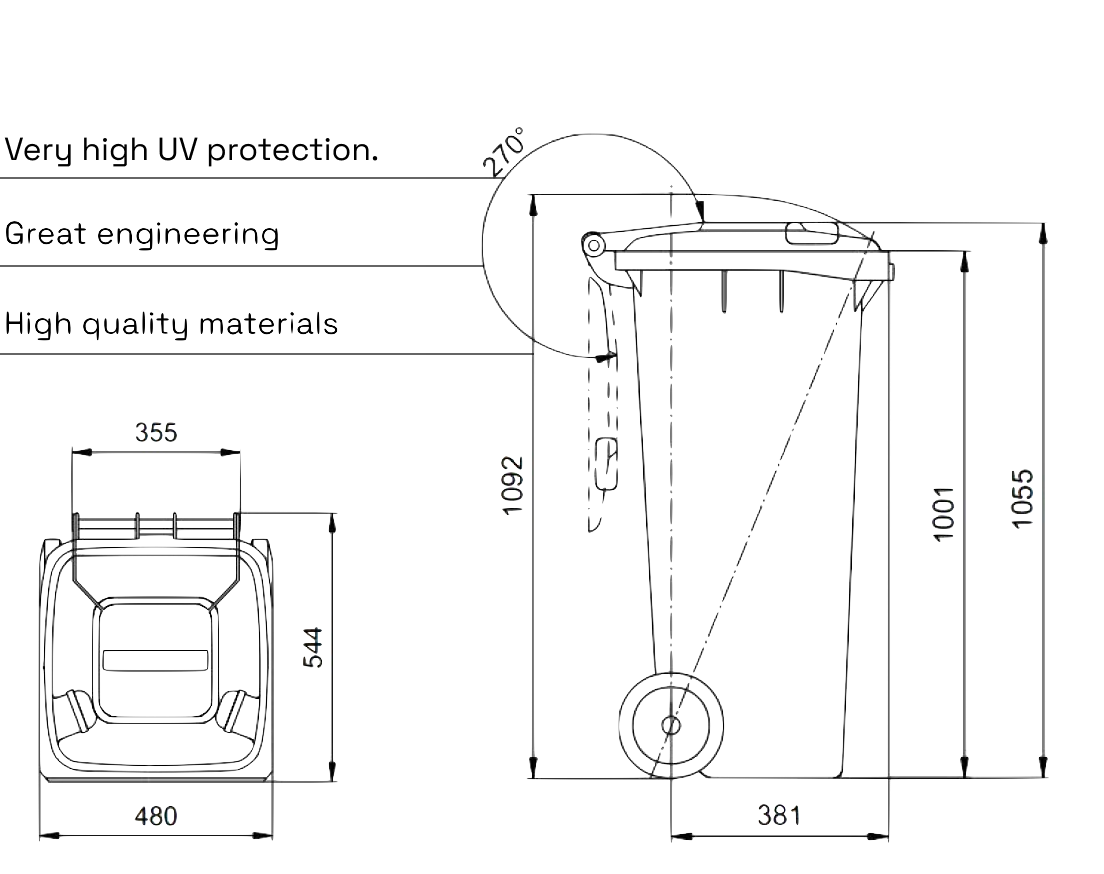

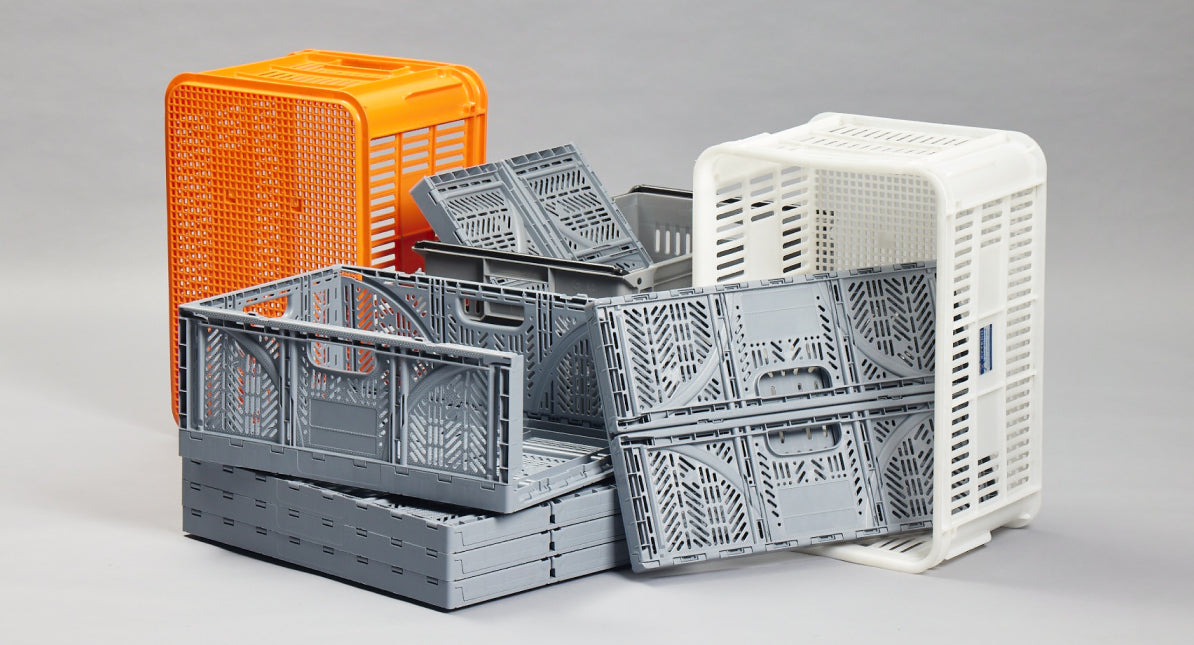

From durability, grip, stackable, reinforcement, colours and branding, everything is considered. We will recommend a range of plastic grades that change finish quality, strength, UV, durability, and fulfil any special requirements (flame resistance, static-free etc.).

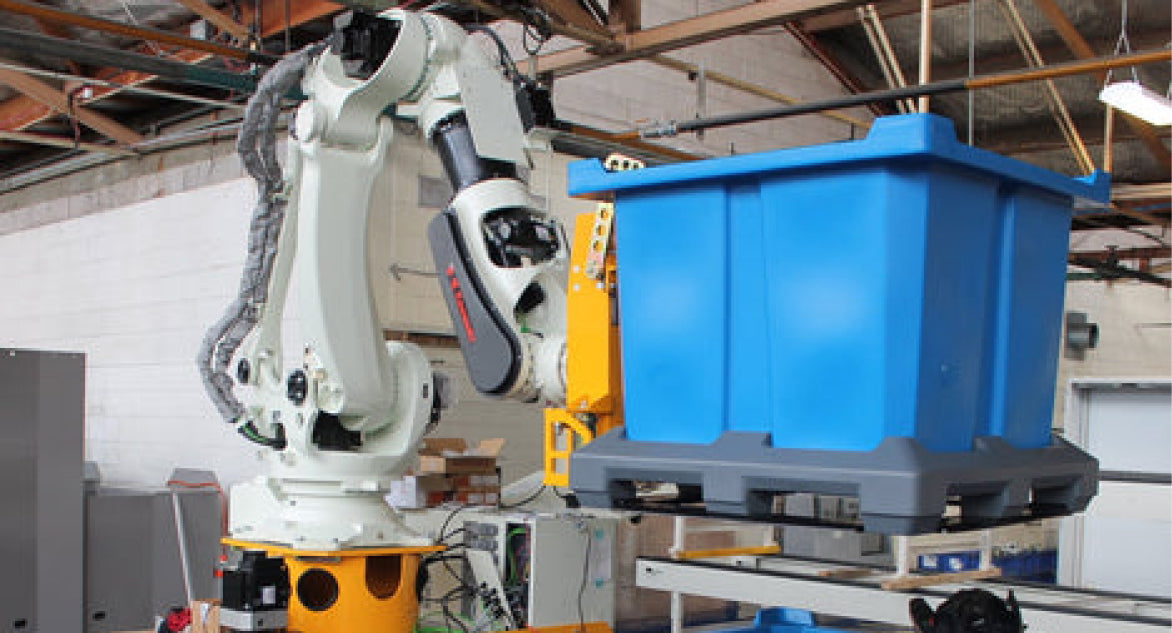

Award Winning Capabilities

trusted by many

We have created plastic products from wheelie bins, to folded bins for some of New Zealands most established companies.

Custom-made v.s. Pre-made Products?

Typically when producing a run of 2,000 or more units, it is often more cost effective to design a custom product that’s perfect for your application, as opposed to settling for the inefficiencies of a stock product. Normally, the cost of product moulds and tooling can also be amortised by our factories, meaning the design process is effectively free.

Attention to detail at every stage

The number one issue that most of our clients face is having challenging part designs. Getting the design and prototyping stages right is difference between mediocrity and excellence. At Rotaform, the entire custom mold-making process from design to production is a collaborative effort and clear feedback at every stage is critical to a successful build.

With our New Zealand factory floor managers averaging 19 years of mold-making and production experience, you can trust that every stage of your project is handled with care by experts.

Learn more about custom-mold manufacturing in these case studies.

How it works

- Talk to us about your product requirements.

- Our design team will advise on trade-offs and design features for the best product.

- Our engineering team will make a preliminary mold and give you a full project quote to approve.

- We make low volume test run, deliver samples, and test quality and performance.

- After quality sign-off, molds are cast, products are manufactured and delivered.

Get access to bulk pricing

Our customer service team is world class.

We are here to help

For general inquiries or questions regarding sales or press, please leave your contact information below and we will get back to you as soon as possible.

Phone

NZ: 09 275 2144

Global: +64 9275 2144

Head Office

59 Montgomery Rd, Mangere,

Auckland 2022

Between small family-run businesses to large scale multinational companies.

Between small family-run businesses to large scale multinational companies.