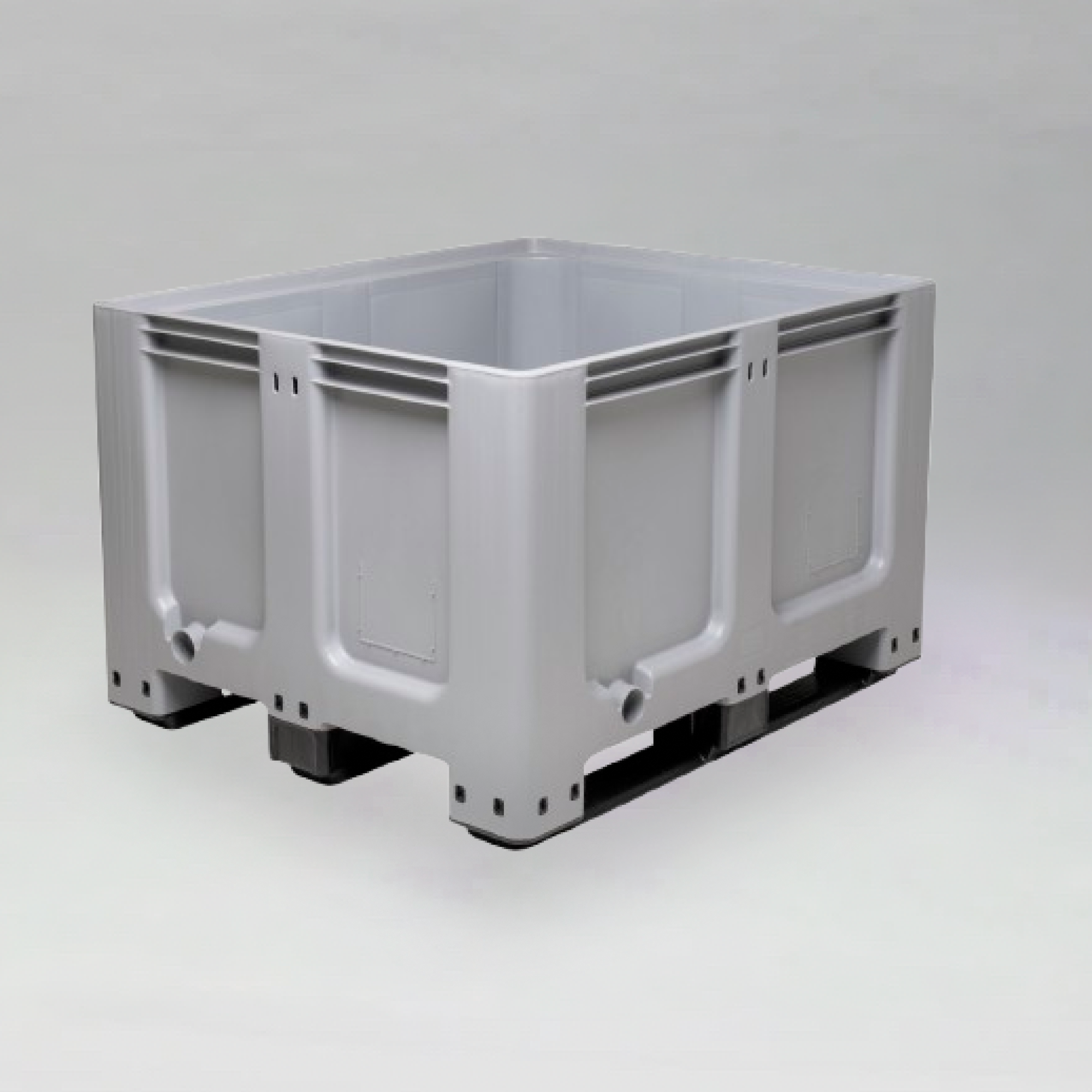

Can Rotaform fermentation tanks be customised?

Yes, we offer extensive customisation options for fermentation tanks. This flexibility allows the tanks to integrate seamlessly into different production setups, enhancing efficiency and convenience. Customisation can also include different tank colours and sizes based on the client's requirements.

What are the benefits of using Rotaform's plastic fermentation tanks?

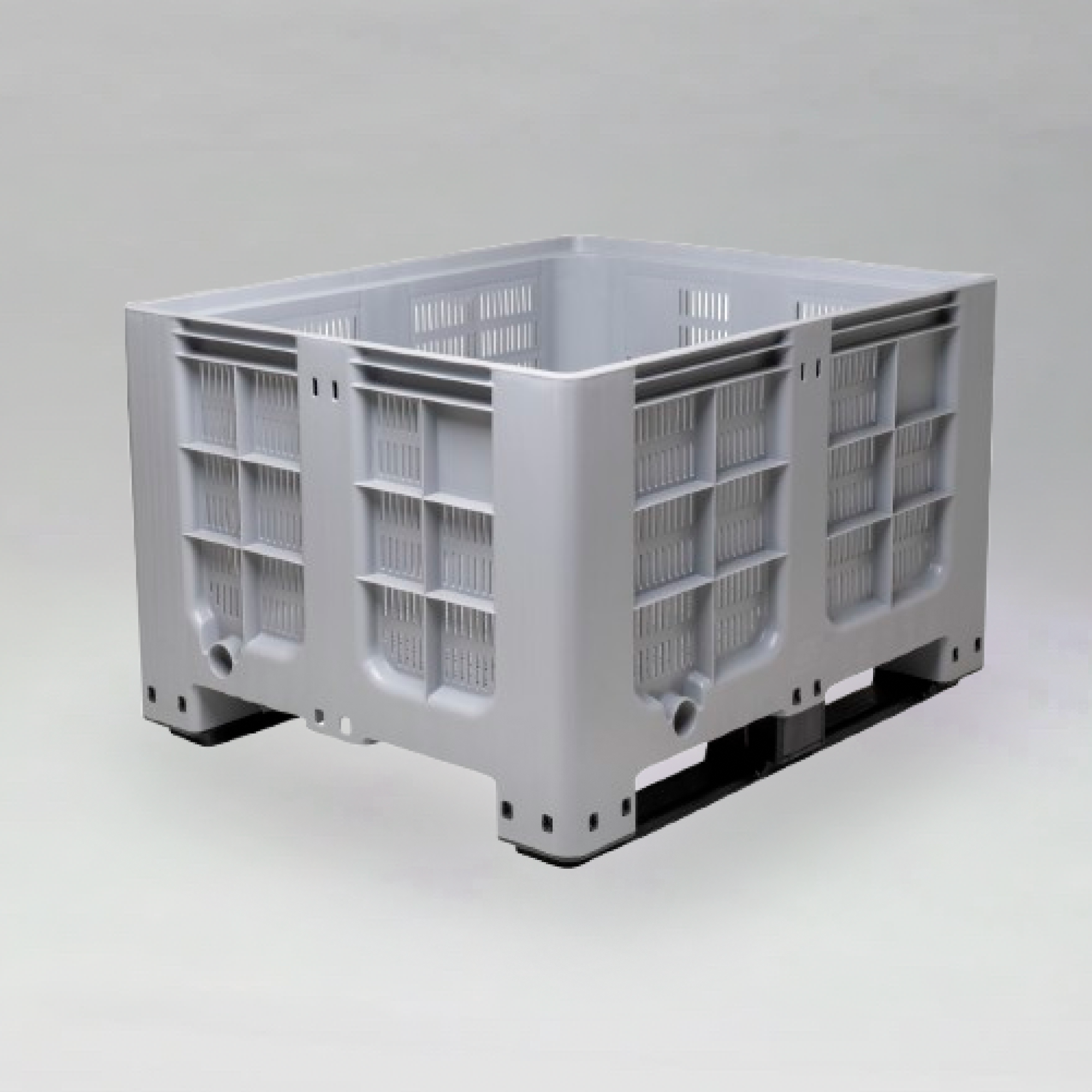

Rotaform fermentation tanks provide several significant benefits. Firstly, our tanks are made from high-quality Medium Density Polyethylene (MDPE). They are robust and can withstand harsh conditions, including impacts and UV exposure.

These tanks also nest together to minimise storage space during the off-season, making them ideal for facilities with limited storage capacity. Compared to stainless steel tanks, Rotaform's MDPE tanks are more affordable, offering a cost-effective solution without compromising quality or performance. Our fermentation tanks are also FDA and EU-approved for food contact, ensuring safety and compliance with food production standards.

What are the typical applications of these fermentation tanks?

Fermentation tanks are versatile and used across several industries:

- Winemaking: These tanks are perfect for fermenting and storing wine, offering a cost-effective alternative to traditional stainless-steel tanks.

- Brewing: Breweries use these tanks for fermenting beer, taking advantage of their durability and customisation options to fit specific brewing needs.

- Cider Production: Ideal for fermenting cider, providing an optimal environment for controlled fermentation processes.

- Food Production: Beyond beverages, these tanks are also used in other food production processes where large-scale fermentation is required.